PRODUCTS & TECHNOLOGY

TECHNOLOGY INNOVATIONS

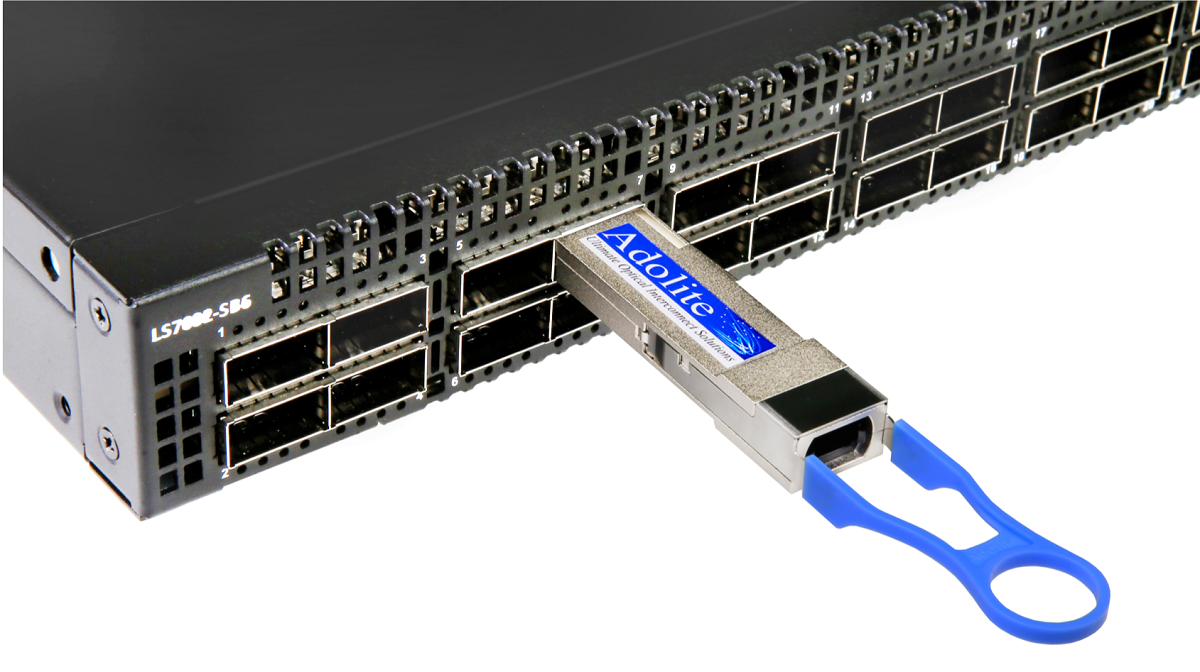

Data centers, cloud computing providers, and 5G mobile operators can unblock their supply chains to support data expansion and speed market innovation and can deliver more data to their customers—faster—with Adolite’s major breakthroughs in materials science and precision manufacturing. The company’s proprietary process replaces embedded fiber with polymer to deliver sophisticated, high-performance optical transceivers, active optical cable (AOC) and on-board optics (OBO)—at 100G (gigabits per second), 400G and beyond.

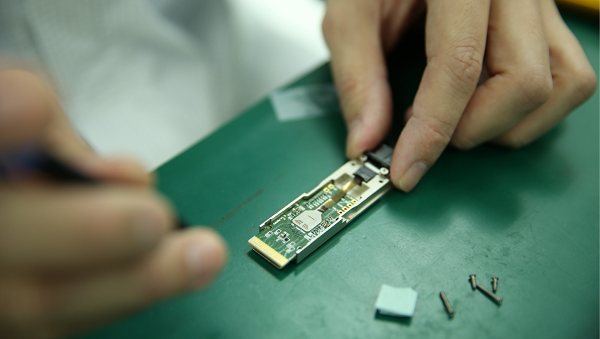

Existing transceiver designs are complex, requiring time-consuming and error-prone production processes owing to multiple lenses, fiber-alignment challenges and complicated assembly. In contrast, Adolite embeds optical waveguides and electrical circuits into a single layer of polymer flexible printed circuit board (FPC) and directly integrates lasers and photo diodes onto the FPC using flip-chip bonding techniques. This simplified physical structure is more flexible and routable at the board level, and can help streamline the production process.

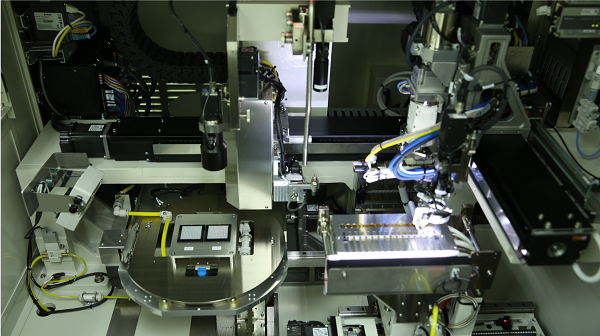

Design innovations lead to increased production volumes

Traditional optical transceiver manufacturing relies on designs that are complex, which means they require time-consuming and error-prone production processes. These designs feature multi-layer, rigid circuit boards, multiple lenses and complex assemblies, and are plagued by fiber alignment challenges. In contrast, our single layer FPC design enables Adolite to manufacture transceivers in high volume with higher throughput.

Unique single-layer flexible printed circuit (FPC) structure

Because we embed optical waveguides and electrical circuits into a single layer of flexible printed circuit board (FPC) and directly integrate lasers and photo diodes onto the FPC using flip-chip bonding techniques, our breakthrough architecture eliminates lenses and the need for fiber alignment, which is a time-consuming and error-prone process. In fact, eliminating optical fiber assembly saves 20-80 seconds in the final production stage.

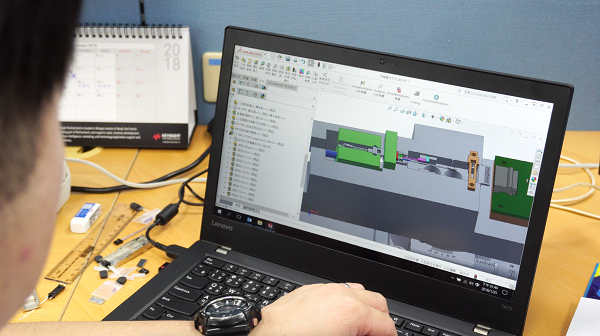

Manufacturing – innovation with execution

Now in our second generation, Adolite’s products are manufactured with the kind of rigorous quality control key for technologies that are the backbone of on-premise and cloud data centers. Adolite uses a line quality-control system that’s error-proof, foolproof and complete final inspection, as well as full traceability. Adolite also uses Industry 4.0 automation and is on track to receive ISO 9001: 2015 certification in the 2nd half of 2018.

PRODUCTS

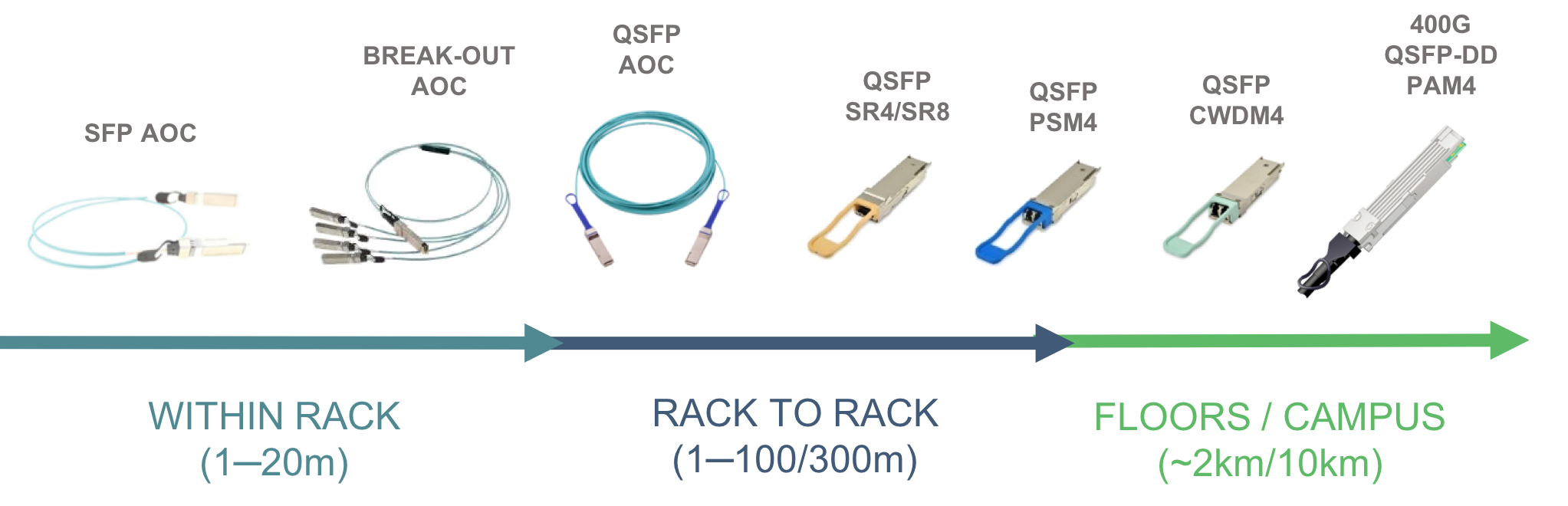

Adolite develops the world’s most sophisticated, high-performance transceivers and on-board optics, including 100G today and a near-term roadmap that includes 200G and 400G. Enabled by major breakthroughs in material science and precision manufacturing, the company is able to produce in extremely high volumes, enabling vendors to scale up quickly to meet customer demand.

From 25G to 400G in active optical cable (AOC), quad small form-factor pluggable (QSFP) and on-board optics (OBO) form factors, our solutions support your data center expansion needs.

Want to learn more?

Adolite’s optical communications products help providers keep up with accelerating data growth to meet market demands.

We help data centers, cloud computing providers and 5G operators unblock their supply chains to support data expansion and speed market innovation.

Contact Us

2933 Bunker Hill Ln.

Suite 140

Santa Clara, CA 95054

+1 (408) 855 – 8800

info@adoliteinc.com